新消息

Sigetronics to Supply KRW 5B Annually in Flip-Chip ESD Devices for Automotive LEDs

Preemptive Entry into the Core Automotive LED Market with Flip-Chip ESD Protection Devices

Commencement of Technology Validation with Global Companies… Manufacturing Capability and Reliability Proven

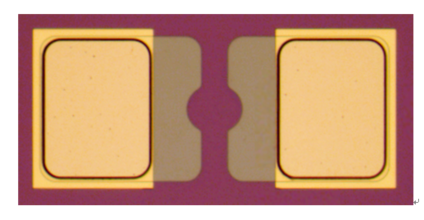

<Sigetronics’ flip-chip transient voltage suppressor (TVS).>

Sigetronics, a compound semiconductor specialist company (CEO: Kyuhwan Shim), announced on the 8th that it has finalized an agreement to supply flip-chip-based electrostatic discharge (ESD) protection devices—an essential component in automotive light-emitting diodes (LEDs) rapidly evolving alongside the expansion of electric vehicles and autonomous driving—to Seoul Semiconductor. The company is preparing for mass production shipments of approximately 1 billion units annually.

Automotive LEDs must simultaneously meet stringent requirements, including high-current operation, high-temperature environments, and long-term usage. In particular, advanced automotive lighting applications such as headlamps, adaptive driving beams (ADB), daytime running lights (DRL), and pixel LEDs demand superior thermal management and long-term reliability, which have become key competitive factors.

Flip-chip-based ESD protection devices eliminate bonding wires, making them highly resistant to vibration and thermal cycling. Their shortened current paths enable faster ESD response and improved protection performance. Even in harsh automotive environments reaching temperatures of 125–150 °C, leakage current characteristics remain stable, making these devices well suited for high-reliability designs. As the adoption of high-power flip-chip LEDs continues to expand, a corresponding transition of protection devices to flip-chip structures has become inevitable.

Accordingly, the use of flip-chip LEDs—offering superior heat dissipation and current spreading—has been accelerating, and ESD protection devices directly connected to LEDs are likewise required to undergo the same structural evolution.

Sigetronics has already developed flip-chip ESD protection device technology and established a mass-production system, enabling the company to aggressively and proactively target the market. The agreement with Seoul Semiconductor is particularly symbolic, marking the company’s entry into full-scale mass production of automotive flip-chip ESD protection devices.

Collaboration outcomes with leading global automotive LED companies are also becoming increasingly visible. Sigetronics has completed pilot production of flip-chip ESD protection devices for Lumileds, a global leader in automotive LEDs, and is currently undergoing technical validation for transition to mass production. Adoption by top-tier global customers is expected to serve as a critical inflection point for expanding Sigetronics’ presence in the automotive protection device market.

Cho Deok-ho, Head of R&D at Sigetronics, stated, “As automotive LEDs rapidly transition toward flip-chip architectures, protection devices are also entering a phase that demands structural innovation. The mass-production supply to Seoul Semiconductor and the pilot production results with Lumileds clearly demonstrate our manufacturing competitiveness and our capability to meet stringent automotive reliability requirements.”

ETNews, hskim@etnews.com, January 8, 2026